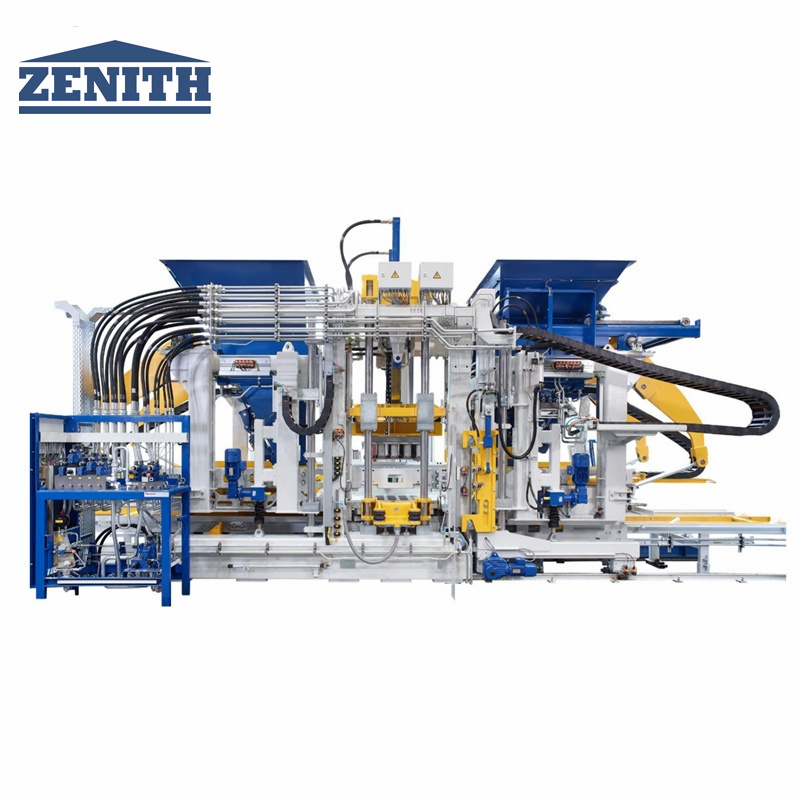

Zenith 1500 Single Pallet Block Making Machine

(1) The high quality servo compaction system named Ultra-Dynamic stands for a very high compaction and extreme dynamics. It therefore guarantees a quick and efficient production of top-quality products. Especially for products with a large volume and also for premium products, which are produced with pre- and intermediate vibration, this vibration system provides many advantages. The system works without an oil bath supporting an eco-friendly and low-maintenance production.

(2) The use of screw fittings for the vibration table, the motor cross beam and the frame side parts is a special feature of this machine. It is unique on the market as it can adapt to customer’s production conditions. The screwed construction also provides for resistant connections and an excellent stability.

(3) The pneumatic mould clamping device provides for an easy mould change. The mould is positioned without further fastenings - e.g. bolts - on the mould holder. It is fixed by the pneumatically operated clamping levers. Optimal vibration results and a longer mould life time are achieved thanks to the individual adjustments of pre- and main vibration. The mould clamping device can now be adapted to mould fastening systems of other machine and mould manufacturers.

(4) A new traverse has been developed for the machine ZENITH 1500-2 which allows to remove the columns individually from the side. This new feature saves a lot of time during maintenance work and the exchange can be carried out much more safely and with less effort. The entire geometry of this assembly including columns is identical to previous machine ZENITH 1500. It is possible to retrofit this new traverse on existing machines.

(5) The self-explanatory and intuitionally visualization concept guarantees for an easy learning of the machine operation. A new diagnostic design supports the operators in choosing the best adjustments. Time-consuming trouble shooting is no longer necessary and production downtimes are reduced to a minimum. By using the latest database technology, all information can be recorded, evaluated and stored. This data is available anywhere thanks to the complete plant networking.

| The basic configuration of zenith 1500 single block making machine | |

| Max.board size | 1,400 mm x 1,200 mm x14 mm |

| Moulding area | According to the layout drawing of the mould |

| Product size | 50 mm - 500 mm |

| Technical parameters of automatic son car | |

| Max. load capacity | 15kg |

| Max. load capacity per insertion rack | As design |

| Max.load capacity every two layers of insertion rack | As design |

| Inside width of support bracket | 1,060mm |

| Layers of insertion rack | Designed as the scheme |

| Distance of insertion rack | As design |

| Mother car driving power | SEW 11KW |

| Product height | |

| Max. height | 500mm |

| Min. height | 30mm |

| Stacking height | |

| Max. Stacking height (including the pallet) | 1,800mm |

| Max. Production area (under the production of standard size) | 1,350*1,050mm |

| Pallet size (standard) | 1,400*1,100mm |

| Steel plate thickness | 14mm |

| Base material silo volume | |

| Excluding pigments silo | 1,500L |

| Machine height | |

| Excluding pigments device | 35T |

| Pallet conveyor | 1.6T |

| Hydraulic device | 3.2T |

| Machine size | |

| Max. total length | 8,250mm |

| Max. total height | 4,650mm |

| Max. total width | 3,150mm |

| Machine technical parameters/ energy consumption | |

| Vibration system | Servo vibration system |

| Vibration table | Maximum: 175KN, 60HZ |

| Top vibration | Maximum: 32KN |

| Hydraulic pressure | |

| Total flow | 540L/ min |

| Operating pressure | 180 bar |

| Max. power | 140 KW |

| Control system | Siemens S7-1500, touch screen console |