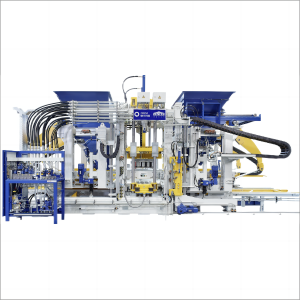

ZN1200C Concrete Block Molding Machine

ZN series products feature high cost performance, adopting German concrete block making equipment manufacturing technology and are more focused on the overall performance, efficiency and product quality.

ZN series products are designed strictly in accordance with Germany production technology. These machines are produced in Fujian, featuring more stable operating performance, higher block making efficiency and lower fault rate and having outstanding advantages in performance, efficiency, energy-saving, environmental protection and so on.

1)High-efficiency vibration: equipped with advanced German vibration technology, the vibration table is composed of a dynamic table and static table. By operating continuously, there is no need for frequent start-up, which can effectively and evenly transform vibration force and better control the product. The forming time of the product is ultimately shorter and the density is higher.

2)Compulsory feeding: the mixing shaft is controlled by Germany SEW feeding motor, and the feedbox, base board and agitator blade adopt high strength HARDOX steel, providing outstanding sealing performance. Through the compound feeding method of compulsory mixing and reciprocating oscillation, the feeding is more uniform and the product quality is greatly improved.

- 3)Frequency conversion control: adopting German frequency conversion control technology, the vibration of the block machine adopts low frequency standby and high frequency operating, improving operating speed and product quality. It can reduce the compact on mechanical parts and motor and prolong the life span of machinery, saving power by 20%-30% compared to operation and control of traditional motors.

4)Full-automatic control: advanced German automatic control technology and visual operation of intelligent interactive system achieves man-machine dialogue, making it easier to operate the machine. And it saves labor cost to the optimal extent, with low fault rate and stable operation. It also has functions of product formula management and collecting operating data.

- 5)High-efficiency hydraulic system: with a high end hydraulic pump and hydraulic valve, the hydraulic operating speed, pressure and stroke can be adjusted based on different products for stable, high efficiency and energy saving operation.

6)Cloud-service platform: with the combination of cloud technology, general technology of data protocol, mobile internet technology, equipment modeling and big data statistics, the data collecting, on-line monitoring, remote system upgrading, remote equipment fault prediction and diagnosis and evaluation of equipment normal production condition can be implemented on the equipment purchased by customers from QGM.

| Maximum Forming Area | 1,280×850mm |

| Block Height | 40-300mm |

| Cycle Time | 14~24S (depending on block type) |

| Servo Vibration Force | 120KN |

| Pallet Size | 1,350×900×(14-45)mm |

| Vibration Motors in Bottom | 4×7.5KW |

| Top Vibration Motors on Tamper Head | 2×1.1KW |

| Control System | SIEMENS |

| Total Power | 86.4kW(included hydraulic system) |

| Total Weight | 17T (including facemix device) |