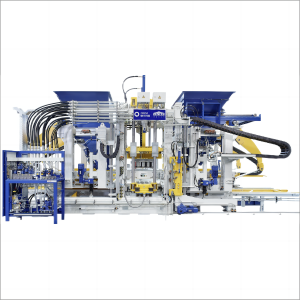

ZN1500-2C Automatic Cement Block Making Machine

- Servo Vibration System

The machine is equipped with the newly developed servo vibration system, which has a dense and high-excited vibration force, thus ensuring production in an efficient way, especially for large products and high-quality products, which need to be produced by pre-vibration and transitional vibration, can achieve a really nice effect.

- Compulsory Feeding

The feeding system is applied with the Germany patented design, which is suitable for the use of construction waste and other special aggregates. What's more, the discharging gate is controlled by SEW motor. The feeding frame, bottom plate & mixing blades are made of high-duty sweden HARDOx steel, which strengthen the sealing performance and prevent the material leakage to guarantee the long service life, feeding uniform for the improved product quality.

- SIEMENS Frequency Conversional Control

SIEMENS Frequency conversional technology was re-innovated and improved by Germany R&D center. The main machine vibration adopts low frequency standby, high frequency operation, which improve the running speed and product quality. At the same time, it reduces the impact on the mechanical parts and the motor prolongs the life of the machine and the motor, and saves about 20%-30% of electricity compared with the traditional motor operation control.

- Fully Automatic Control

Perfectly combine the automation technology and system from Germany. The automatic control is of easy operation, low failure ratio and high reliability. At the same time, it has the functions of product formula management and operation data collection.

- High-efficient hydraulic system

The hydraulic pump & valve are from international brand, which adopt high dynamic proportional valve and constant output pump to adjust the speed & pressure, with the features of high-stability, high efficiency and energy-saving.

- lntelligent Cloud System

QGM intelligent equipment cloud system realizes online monitoring, remote upgrade, remote fault prediction and fault self-diagnosis, equipment health status evaluation; generates equipment operation and application status reports and other functions; with the advantages of remote control & operation, quick troubleshooting &maintenance for the clients. Everything is interconnected, and the production and operation of equipment can be seen through the network in every corner of the world.

|

Max. forming area |

1,300*1,050mm |

|

Height of finished product |

50-500mm |

|

Moulding cycle |

20-25s(following the product shape) |

|

Exciting force |

160KN |

|

Pallet size |

1,400*1,100/1200*(14-50)mm |

|

Forming block number |

390*190*190mm(15 block/ mould) |

|

Vibration table |

4*7.5KW |

|

Top vibration |

2*1.1KW |

|

Electrical control system |

SIEMENS |

|

Total installed capacity |

111.3KW |

|

Total weight |

18.3T(without face material device) 28.2T(with face material device) |

|

Block Type |

Output |

ZN1500-2C Block Making Machine |

|

240*115*53mm |

Number of formed blocks(block/ mould) |

84 |

| Square meter/ hour (m2/ hour) |

400-420 |

|

| Square meter/ day (m2/ 8 hours) |

3180-3360 |

|

| Number of block (blocks/ m2) |

36 |

|

|

390*190*190mm |

Number of formed blocks(block/ mould) |

15 |

| Cubic meter/ hour (m3/ hour) |

32-34 |

|

| Cubic meter/ day (m3/ 8 hours) |

254-271 |

|

| Number of block (blocks/ m3) |

71 |

|

|

400*400*80mm |

Number of formed blocks (block/ mould) |

3 |

| Cubic meter/ hour (m3/ hour) |

69.1-86.4 |

|

| Cubic meter/ day (m3/ 8 hours) |

553-691.2 |

|

| Number of block (blocks/ m3) |

432-540 |

|

|

245*185*75mm |

Number of formed blocks (block/ mould) |

15 |

| Cubic meter/ hour (m3/ hour) |

97.5-121.5 |

|

| Cubic meter/ day (m3/ 8 hours) |

777.6-972 |

|

| Number of block (blocks/m3) |

2160-2700 |

|

|

250*250*60mm |

Number of formed blocks (block/ mould) |

8 |

| Suqare meter/ hour (m3/ hour) |

72-90 |

|

| Square meter/ day (m3/ 8 hours) |

576-720 |

|

| Number of brick (blocks/ m3) |

1152-1440 |

|

|

225*112.5*60 |

Number of formed blocks (block/ mould) |

40 |

| Square meter/ hour (m2/ hour) |

150-160 |

|

| Square meter/ day (m2/ 8 hours) |

1200-1280 |

|

| Number of block (blocks/ m2) |

39.5 |

|

|

200*100*60 |

Number of formed blocks (block/ mould) |

54 |

| Square meter/ hour (m2/ hour) |

138-150 |

|

| Square meter/ day (m2/ 8 hours) |

1100-1200 |

|

| Number of block (blocks/ m2) |

50 |

|

|

200*200*60 |

Number of formed blocks (block/ mould) |

30 |

| Square meter/ hour (m2/ hour) |

180-195 |

|

| Square meter/ day (m2/ 8 hours) |

1440-1560 |

|

| Number of block (blocks/ m2) |

25 |