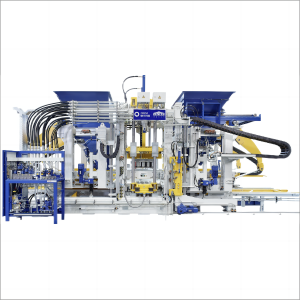

ZN1200S Paver Block Making Machine

1)The Zenith block making machine adopts frequency conversion control to reduce the starting current of the motor. This achieves the synchronous operating of vibration assembly and solves the inertia problem motor when stopping, saving power by 20%-30%.

2)With the adoption of Germany Siemens PLC and Siemens touch screen control, the operation is easy, the overall fault is low and operating data can be saved permanently.

3)The hydraulic system is controlled by proportional valve to automatically adjust the flow during production, improving the operating stability and prolonging the service life of the cylinder.

4)The feeding car adopts 360˚ rotary feeding method with fast speed and uniform distribution, applicable to various raw materials and moulds.

- 5)After a cabonitriding treatment, the mould is resistant to wear and has a service life of over 50% longer than general moulds.

6)The machine is equipped with real-time fault diagnosis and alarming system.

7)The vibration table is connected with the workbench and the hole spacing of the eccentric shaft is enlarged, reducing the loss of energy transfer, enlarging the effictive vibration area and improving the vibration efficiency.

| Pallet Size | 1,200*1,150mm |

| Forming Area | 1,100*1,080mm |

| Height of Finished Products | 50-300mm |

| Cycle Time | 15-25s(as per mould) |

| Vibration Force | 120KN |

| Bottom Vibration | 2*15KW(SIEMENS) |

| Top Vibration | 2*0.55KW |

| Power | 70.35KW |

| Total Weight | Main Machine:14.98T

With facemix device: 18.49T |

|

Block Type |

Dimension (mm) |

Pictures |

Qty/Cycle |

Production Capacity (Per 8hs) |

|

Hollow Block |

390*190*190 |

|

12 | 14,400-16,800 pcs |

|

Rectangular Paver |

200*100*60-80 |

|

36 |

1,000-1,200m2 |

|

Interlocks |

225*112.5*60-80 |

|

32 |

35,200-38,400 pcs |

|

Curstone |

500*150*300 |

|

4 |

4,400-5,600 pcs |